How does a dry aging cabinet work?

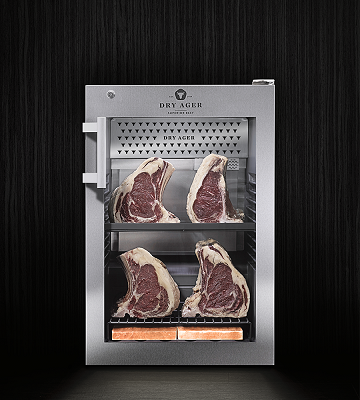

The most important thing about meat maturing is a perfect climate. Keeping this for many butchers in the past was the great difficulty. The dry aging cabinet has solved this problem and – thanks to the format – simultaneously enabled operation in private households.

What makes a good dry aging fridge?

A good maturing cabinet needs a good ventilation system and an exact, electronic temperature control, which also intercepts variations in the outside temperature. For the conditions do not agree, spoils the flesh.

Temperature control

Meat is one of the most temperature-sensitive foods. During storage, hazardous pathogens such as salmonella can form. Therefore it is important to cool the food properly and constantly from the beginning. This starts right after the slaughter and also applies to the maturing process. In order for meat to dry – and thus become the coveted Dry Aged Beef – it needs an ambient temperature of approx. 1 to 3 ° C.

The right climate

Meat is not only sensitive to temperature but also sensitive to humidity. In order for the Dry Aged Meat to dry dry, the humidity in the ambient air must not be too high. Otherwise the water does not evaporate. In order to maintain the humidity in the refrigerator compartment, many manufacturers work with water tanks in the unit. This technique has two disadvantages: it requires its own water connection and the tanks are particularly susceptible to germs.

The developers of the DRY AGER® cabinet have therefore devised the intelligent HumiControl® system. It does not need either a water connection, a tank and a constant humidity in the ambient air of 60 to 90%.

Sufficiently ventilated

If you return home after a long day, you know the phenomenon of “stale” air. The oxygen in the air consumes, even without breathing creatures in it. The same goes for the refrigerator compartment. Oxygen is important, however, to allow the meat to oxidize and the famous Dry Aged crust forms. In addition, germs can form in “standing” air. Good ventilation in the refrigerator compartment is therefore crucial. In addition to the AirReg® ventilation system, the DRY AGER® additionally operates with an activated carbon filter and a sterilization box. Thus the air in the frdige always remains fresh and clean.

Perfect conditions

- Perfect temperature: 0-4 C °

If the temperature is above this, the germs multiply. At temperatures below the freezing point, the enzymes can not work and the meat does not ripen. - Perfect humidity: 80-85%

It is possible to vary the humidity easily between 60-90%. This slightly changes the flavor, which makes the final product more individual. At higher values, however, the possibility of mold attack increases. At low levels, the outer crust dries deeper and deeper. In both cases, more of the finished product has to be cut, which results in a loss of the self-weight of 30-40%. - Perfect ventilation: 0.5 – 2 m / s

If the air is not sufficiently exchanged, microbiological cultures multiply too quickly and let the meat spoil. If the exchange is too high, the meat can dry out.